Product Description:

The Automatic Rigid Box Making Machine is an advanced piece of equipment designed to meet the growing demands of the packaging industry. This machine specializes in producing high-quality rigid boxes with exceptional precision and efficiency, making it an indispensable asset for businesses focusing on premium packaging solutions. With a compact structure, the machine is engineered to save valuable floor space while delivering outstanding performance.

Powered by a reliable 220V/380V system, the Automatic Rigid Box Making Machine ensures consistent and stable operation, suitable for various industrial environments. This dual voltage capability allows flexibility in installation and usage across different regions and manufacturing facilities. The machine’s power system is optimized to handle the intricate processes involved in rigid box production without compromising speed or accuracy.

One of the standout features of this machine is its ability to handle greyboard materials with dimensions of L*W*T: 650*550*3 mm or 74*74*1 mm. The greyboard serves as the sturdy core of the rigid box, providing durability and robustness. Additionally, the machine is equipped to process face paper with dimensions of L*W*T: 700*420*300 mm or 120*60*80 mm, which forms the outer decorative layer of the box. This capability ensures that the finished boxes not only have structural integrity but also exhibit a refined and attractive appearance.

The compact structure of the Automatic Rigid Box Making Machine enhances its usability in production lines with limited space. Despite its small footprint, the machine maintains high efficiency and throughput, making it ideal for businesses that require both quality and quantity. Its design facilitates easy integration with other packaging equipment, such as Automatic Box Packing Machines, streamlining the entire packaging process from box making to final packing.

Precision is a critical factor in rigid box manufacturing, and this machine excels with a positioning accuracy of 0.05mm. Such a high degree of accuracy guarantees that every box produced meets strict quality standards, with perfectly aligned edges and seamless finishes. This level of precision reduces material waste and enhances the overall aesthetic appeal of the boxes, which is vital for luxury product packaging.

In addition to producing rigid boxes, the machine is often used in tandem with an Automatic Box Packing Machine, creating a fully automated packaging line. This integration significantly boosts productivity by minimizing manual intervention and accelerating the packaging workflow. The synergy between the Automatic Rigid Box Making Machine and the Automatic Box Packing Machine ensures that products are securely packed in customized rigid boxes ready for shipment or retail display.

Overall, the Automatic Rigid Box Making Machine is a versatile and efficient solution for manufacturers seeking to elevate their packaging capabilities. Its robust power system, precise handling of greyboard and face paper materials, compact design, and exceptional positioning accuracy make it a top choice for producing premium rigid boxes. When combined with an Automatic Box Packing Machine, it forms a comprehensive automated packaging system that meets the highest standards of quality and productivity in the packaging industry.

Features:

-

Product Name: Rigid Box Making Machine

-

Power: 220V/380V

-

Warranty: 1 Year

-

Positioning Accuracy: 0.05mm

-

Control System: PLC

-

Operation: Automatic

-

High precision with positioning accuracy of 0.05mm ensures quality output

-

Equipped with advanced PLC control system for efficient and reliable operation

-

Designed as an Automatic Paper Box Making Machine for streamlined production

-

Functions as an Automatic Box Packing Machine to enhance packaging efficiency

-

Fully Automatic Box Packing Machine operation reduces manual labor and increases productivity

Technical Parameters:

|

Size

|

Customized

|

|

Operation

|

Automatic

|

|

Design

|

Customized

|

|

Positioning Accuracy

|

0.05mm

|

|

Material

|

Paperboard

|

|

Face Paper Size (L*W*T)

|

700*420*300 / 120*60*80 (mm)

|

|

Control System

|

PLC

|

|

Finished Product Size (L*W*H)

|

400*300*140 / 55*35*12 (mm)

|

|

Usage

|

Packaging

|

|

Warranty

|

1 Year

|

Applications:

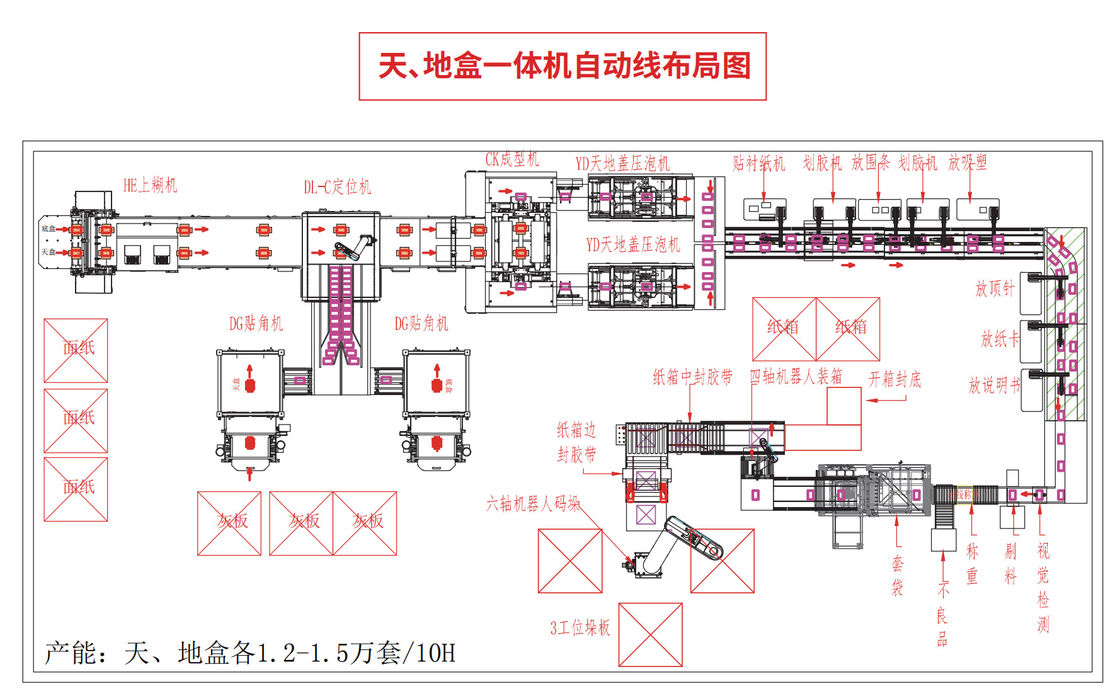

The Intelligent Integrated Top-Bottom Box Production Line, model LY-HB3000CZ, is a state-of-the-art Automatic Paper Box Making Machine designed for high-efficiency packaging applications. Originating from China and certified with CE, this rigid box making machine stands out in the packaging industry for its precision and reliability. With a minimum order quantity of just one set and a delivery time of 30 days, it is an ideal solution for businesses seeking to enhance their production capabilities swiftly and effectively.

This Automatic Paper Box Making Machine is primarily used in the packaging sector, specifically tailored to produce rigid boxes with finished product sizes ranging from 400*300*140 mm to 55*35*12 mm. Its automatic operation ensures consistent quality and reduces manual labor, making it perfect for packaging manufacturers who require high-volume output with minimal errors. Packaged securely in a wooden case, it guarantees safety during transportation and ease of installation upon arrival.

The LY-HB3000CZ model excels in various application occasions and scenarios. It is widely utilized in luxury packaging industries, including cosmetics, electronics, jewelry, and premium gift boxes, where the demand for sturdy and aesthetically pleasing rigid boxes is high. Retailers and manufacturers benefit from this machine's capability to produce top-bottom rigid boxes quickly, thus meeting tight delivery schedules and maintaining competitive advantage.

Additionally, this Automatic Paper Box Making Machine is highly suitable for custom packaging businesses that require flexibility in box dimensions and designs. Its automatic operation streamlines the production process, enabling companies to handle bulk orders with ease while ensuring consistent product quality. The machine’s CE certification assures users of its compliance with international safety and quality standards, making it a trusted choice worldwide.

In summary, the Intelligent Integrated Top-Bottom Box Production Line LY-HB3000CZ is an indispensable asset for businesses involved in packaging that demand efficiency, precision, and durability. Whether for small-scale custom packaging or large-scale industrial production, this Automatic Paper Box Making Machine offers unparalleled performance, reliability, and versatility, making it an excellent investment for future growth.

Customization:

Our Intelligent Integrated Top-Bottom Box Production Line, model LY-HB3000CZ, is an Automatic Rigid Box Making Machine designed to meet your specific packaging needs. Manufactured in China and CE certified, this Automatic Paper Box Making Machine offers a compact structure and high speed operation, ensuring efficient production of high-quality rigid boxes.

We provide full product customization services, allowing you to specify the size and paperboard material according to your requirements. The machine supports a paper stacking height of up to 800mm, enabling continuous and stable production. With a minimum order quantity of just 1 set and a delivery time of 30 days, we ensure timely supply and flexibility for your business.

Our Automatic Box Packing Machine integrates seamlessly with your production line, and we accept T/T payment terms for your convenience. Trust our expertise to deliver a tailored solution that enhances your packaging process with precision and reliability.

Support and Services:

Our Rigid Box Making Machine is designed to deliver high precision and efficiency in manufacturing rigid boxes. For technical support, our team of experts is available to assist with installation, operation, and troubleshooting to ensure optimal performance of your machine.

We offer comprehensive maintenance services including routine inspections, parts replacement, and software updates to keep your machine running smoothly. Our support also includes training sessions for operators to maximize productivity and minimize downtime.

In addition, we provide customization options and upgrades tailored to your specific production needs. Whether you require modifications for different box sizes or enhanced automation features, our technical team can guide you through the available solutions.

We are committed to delivering prompt and reliable support to help you achieve consistent quality and efficiency in your box making operations. Please refer to your user manual for detailed operating instructions and maintenance guidelines.

Packing and Shipping:

Our Rigid Box Making Machine is carefully packaged to ensure it reaches you in perfect condition. Each machine is securely wrapped with protective materials to prevent any damage during transit. The packaging includes sturdy wooden crates reinforced with cushioning materials to absorb shocks and vibrations.

For shipping, we offer multiple options tailored to your location and urgency. The machine can be shipped via sea freight, air freight, or land transportation. All shipments are tracked and insured for your peace of mind. Additionally, we provide detailed handling instructions to ensure safe unloading and installation at your site.

We are committed to delivering your Rigid Box Making Machine promptly and safely, supporting your business with reliable equipment and excellent service.

FAQ:

Q1: What is the brand name and model number of this rigid box making machine?

A1: The brand name is Intelligent Integrated Top-Bottom Box Production Line, and the model number is LY-HB3000CZ.

Q2: Where is the rigid box making machine manufactured?

A2: This machine is manufactured in China.

Q3: Does this machine have any certifications?

A3: Yes, the machine is CE certified, ensuring it meets European safety and quality standards.

Q4: What is the minimum order quantity for the LY-HB3000CZ rigid box making machine?

A4: The minimum order quantity is 1 set.

Q5: What are the payment terms and delivery time for this product?

A5: The payment terms are T/T (Telegraphic Transfer), and the typical delivery time is 30 days.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!